Floor Marking Placement

he following is a transcript of the Floor Marking Placement [Infographic]:

Placement And Colour Guide to Floor Marking

Floor Marking Applications:

- Purple Tape - Finished Goods

- White Tape - 5S Cart Storage

- Blue Tape - Part Organisation

- Printable Tape - Traffic Marking

- White Tape - Work Area

- Green Tape - Part Organisation

- Black Tape - Part Organisation

- Yellow Tape - Pallet Storage

- T's & Corners

- Red/White Stripe - Keep Clear Area

- Stop Sign for Traffic

- Black/Yellow Stripe - Hazardous Area

- Yellow Tape - Traffic Flow

- Black/White Stripe - Keep Clear Area

- Black/Yellow Stripe - Electrical Area

- Green Tape - Safety Area

- Footprint Cutouts

- Glow-in-the-Dark Floor Marking

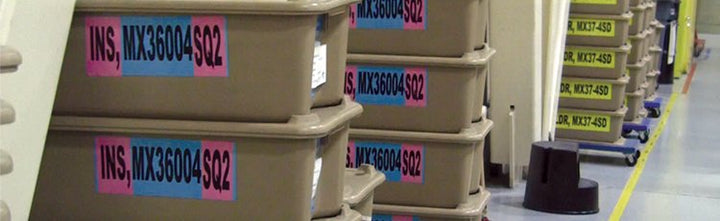

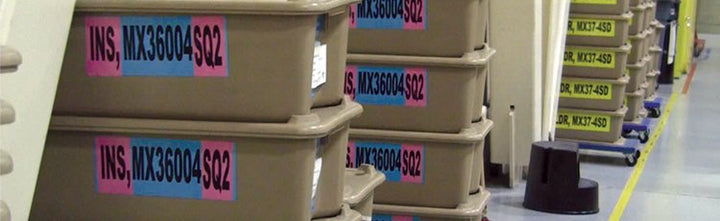

Label Applications

- Fire Safety Label

- Door Safety Sign

- Emergency Eye Wash Label

- Dock Identification Label

- Forklift Safety Sign

- Rack & Shelf Labels

- Labelled Inventory Locations

- Shelf & Bin Labels

Widely Used Floor Marking COLOURS & PATTERNS

While there are no specific floor marking colour requirements, the following is a colour-coding guide popular in many facilities.

YELLOW

When used for safety purposes, indicates caution. For organisation purposes, used for pedestrian paths, vehicle paths, aisles, work areas and storage areas.

WHITE

Often used for general purposes, such as outlines around equipment or storage racks.

RED

For safety purposes, used as a hazard indicator. For organisational purposes, used to mark the boundaries of a defect product area or scrap material area.

ORANGE

For safety purposes, used to indicate a level of caution more serious than yellow. For organisational purposes, used to indicate materials or product held for inspection.

BLACK/GREEN/BLUE/PURPLE

Various colours can be used for organisational purposes, such as indicating raw materials, work-in-progress materials or finished goods.

BLACK/YELLOW STRIPE

When used for safety purposes, indicates caution. For organisational purposes, used for pedestrian paths, vehicle paths, aisles, work areas and storage areas.

BLACK/WHITE STRIPE

Often used for general purposes, such as outlines around equipment or storage racks.

RED/WHITE STRIPE

Often used to indicate areas that must be kept clear for safety reasons (like around exit points, electrical panels, or hazardous equipment).

Types of Floor Marking Tapes

Be sure you always have the right floor marking tape for the job. For example, PathFinder offers all of the following:

- Rigid™ aisle marking tape is designed to handle heavy traffic and provide long life even in high-traffic locations

- The TREAD™ line of anti-slip floor tapes can prevent the most common workplace injury—slips and falls by adding traction to potentially slick areas such as entryways or stairs

- REFLECT™ high-visibility floor tape and stick-ons are ideal for any situation requiring increased visibility, including low-light conditions

- Glow-in-the-dark floor tapes highlight the way to safety exits in emergency power outage situations